Supporting Products

We have developed a range of shaped items with high chemical, thermal and abrasion resistance to withstand the harshest environments.

Our ACCSIL brick range comprises highly acid resistant silica-alumina and carbon bricks, alongside higher abrasion resistant materials such as alumina, silicon nitride and silicon carbide. These can be shaped to your requirements.

We also offer complementary materials such as acid resistant rubber linings, insulating cellular glass block, ceramic packing for acid towers, refractory brick for high temperature zones, and an assortment of other supporting products that can be included to further enhance your lining system with increased structural integrity or insulating effects, as per your requirements.

ACCSIL Bricks

ACCSIL Bricks is the ACCS brand of Acid Resistant Bricks. They are manufactured from high quality raw ingredients: silica-alumina, carbon, or silicon-carbide. The composition can be altered depending on your bespoke requirements. ACCSIL Bricks are extremely hard wearing and resistant to freeze-thaw conditions. Brick lined systems offer the greatest operational life of all of the systems we offer.

ACCSIL Bricks – High Silica (Accrington NORI equivalent)

Refractory Brick – High Alumina

Carbon/Graphite Brick – High Carbon

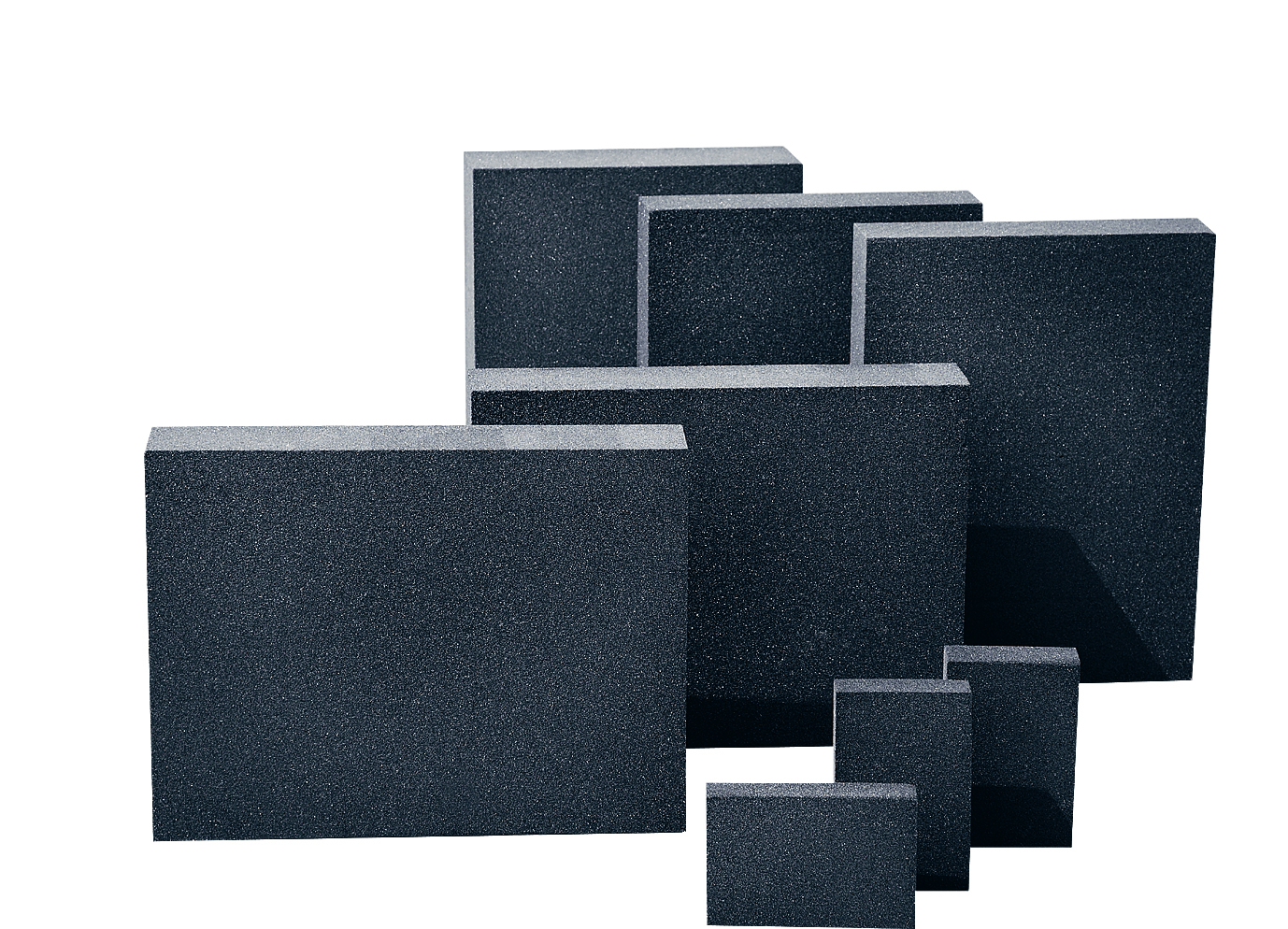

Cellular Glass Block (CGB) – Insulation

CGB offers excellent thermal insulation, whilst also providing high levels of corrosion protection. CGB is the material of choice for areas where temperature stability is essential. Also due to low density of this material it is excellent for vertical protection applications, such as chimney internals.

Glass Matting

Glass Matting and veil are structural enhancement materials that will provide a composite mesh structure to a coating or render material. This offers excellent chemical resistance whilst maximising mechanical strength against structural movement, particularly effective with resin linings.

PTFE

PTFE is used where a near impervious membrane is required. PTFE membranes can be applied quickly and efficiently and offer resistance to a broad range of concentrated chemicals.

Rubber

Rubber linings offer a flexible protective lining system for steel vessels, or areas where mechanical movement of the substrate is expected. They offer a monolithic corrosion resistant barrier to chemical attack of the substrate. We offer a variety of different grades to suit different chemical environments.