Silicate-Based Materials

Our silicate-based materials are recommended against all acids such as high concentration nitric, sulphuric & chromic acids. They are ideal for acid fumes, jointing acid resistant bricks, concreting and rendering, e.g., for chimney and sulphur pit applications.

Their maximum operating temperature can reach up to 900°C.

They are not recommended for Hydrofluoric Acid (HF) or fluorine containing acids/salts, any alkalis, steam, or freeze-thaw applications.

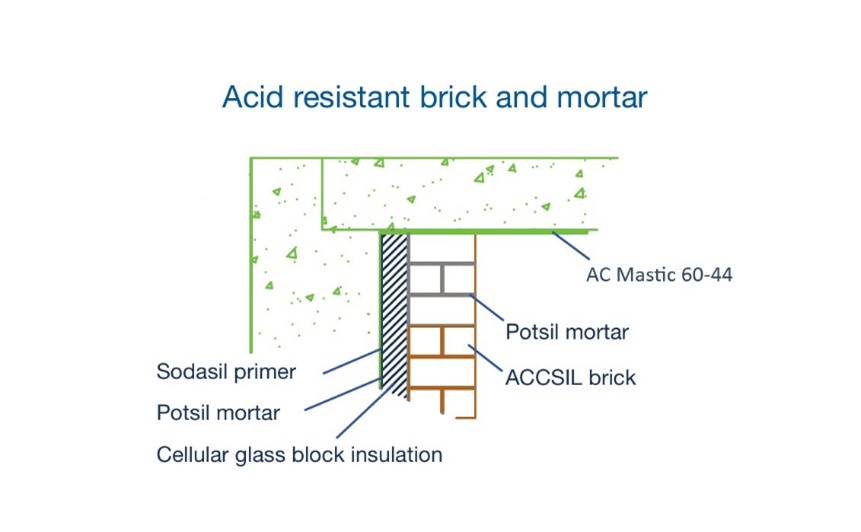

Potsil

Potsil is our recommended mortar product for the majority of acidic and high temperature applications. It is regularly used in sulphur pits and chimney applications.

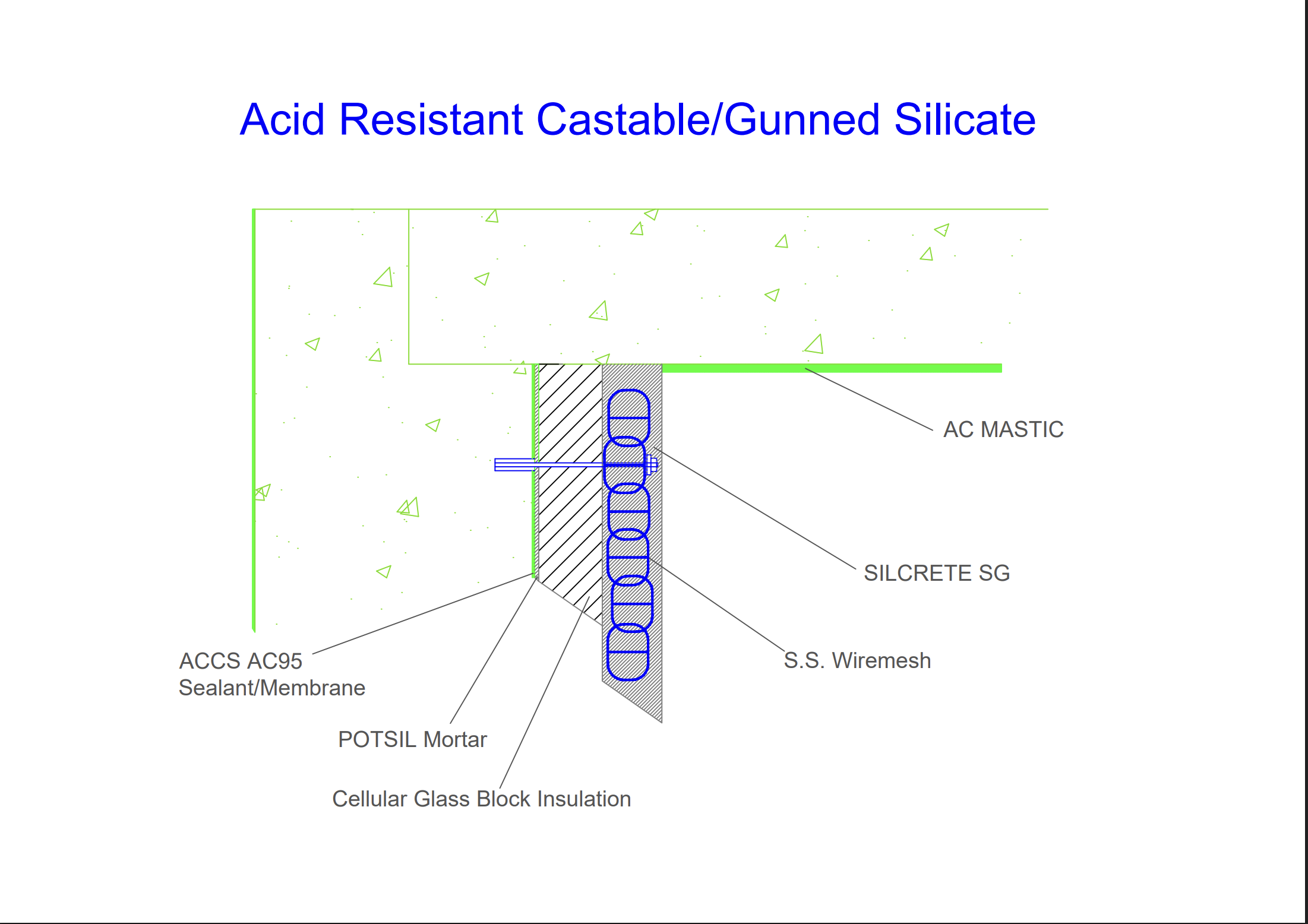

Silcrete

Silcrete is our recommended concrete product where masonry applications are not possible, or where a high build lining system is required in a reduced time frame. Silcrete is our recommended material for sulphur pit applications.

Furan

Furan is our recommended mortar product for applications that are exposed to elevated temperatures, both acid and alkaline environments, and where freeze/thaw environments occur. This has meant that they have been extensively used in effluent processing area and making them ideal for external trenches and storage bunds.

Sodasil

Sodasil is our recommended primer material where high temperature environments occur, and a joint sealant is required.